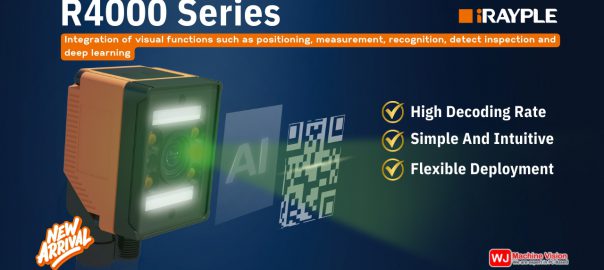

R4000 Series

AI-enabled R4000 series code readers achieve high decoding rates and support various 1D and 2D codes, even in complex scenarios. They feature three fully integrated illumination options: transparent, polarized, and diffused lights, each with R, G, and B color options, making them adaptable to a wide range of applications. Rotatable connectors and a compact design allow for easy installation in space-constrained areas.

High Decoding Rate

Self-developed AI Algorithms Satisfy Complex Scenes Code Reading

- AI Enable Algorithm, accurate positioning, stable decoding time and accurate decoding

- Multi-configuration Polling

- Fully integrated multi-illumination type and multi-spectrum options

Simple And IntuitiveOne-click training for easy

debugging, intuitive results indication in any view

- One-click training, easy for deployment and debugging

- Dual-aimer indicates the central of FOV

- Intuitive red and green lights indicate decoding result in any view

Flexible Deployment

Small size and rotatable connectors meet flexible installation demands

- Small size, and rotatable connectors flexible for installation

- Multi-camera networking, single camera summary output, easy to operate

- EasyID Setup & Debugging Tool, minimal set up

/ADAM-3600_68_B20151015173935.png)