Description

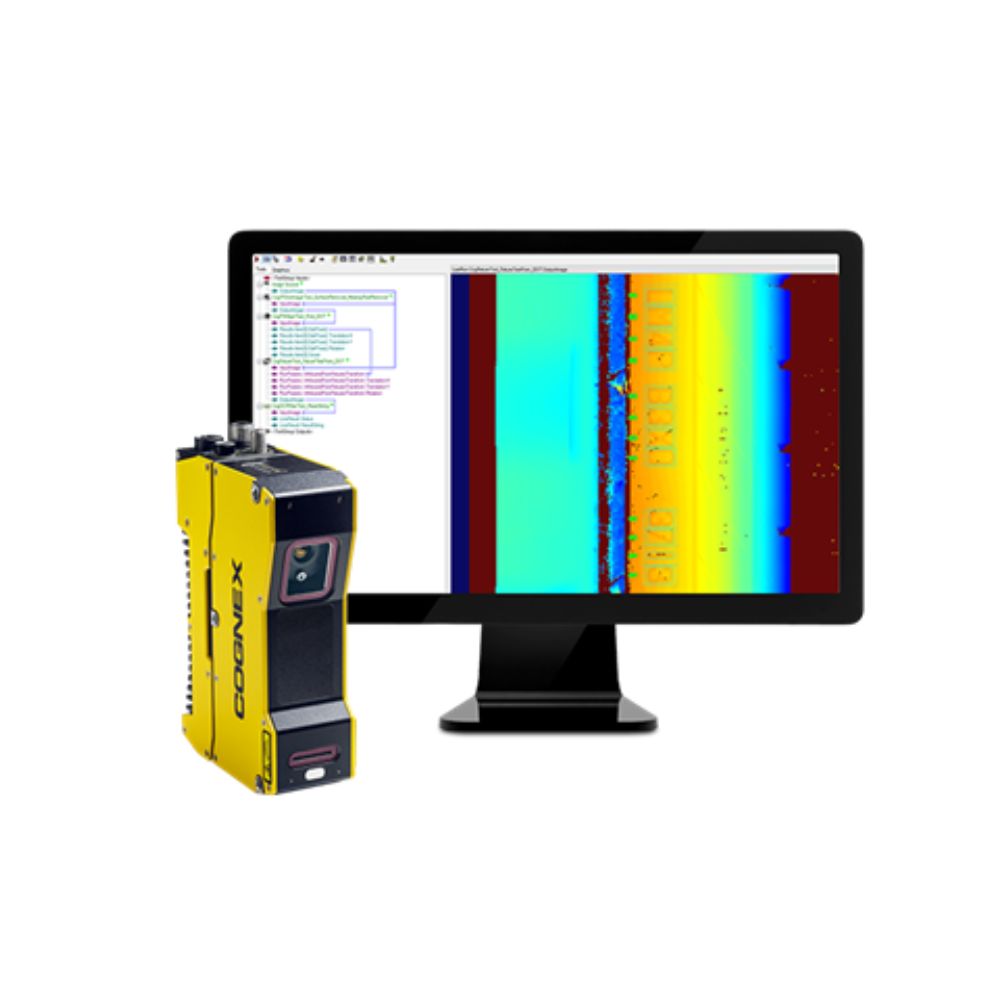

3D-L4000 with VisionPro

Optimize your product quality with high-speed, high-resolution 3D inspections

The 3D-L4000 with VisionPro combines laser triangulation with advanced image formation to create highly-detailed, three-dimensional renderings of parts under inspection. From these topographical renderings, you can capture precise measurements of every surface-level feature including length, width, height, tilt, and volume.

With a rugged, IP-65 rated design and a compact form factor, the 3D-L4000 with VisionPro easily fits into any production environment and offers manufacturers of all size:

- A versatile solution to automate both 2D and 3D vision tasks

- Full factory calibration to simplify deployment

- Contrast independent inspection for higher detection capability

Complete 2D and 3D machine vision solution

- Meet any application requirement with an extensive range of sensor options and the ability to combine 3D and 2D cameras

- Quickly deploy inspection, OCR, and presence/absence applications with intuitive software

- Connect up to four 3D displacement sensors for centralized management

Full factory calibration for easy setup

- Achieve micron-level accuracy

- Prevent misalignment and motion errors

- Generate measurements in real-world units

- Establish consistency across production lines

- Achieve higher resolution and accommodate wider fields of view

- Simplify multi-head analysis with 3D image stitching

Contrast independent inspection

- Detect objects on challenging backgrounds, including reflective surfaces and dark parts against dark surfaces

- Generate intensity data of different regions concurrently

- Enhance texture of 3D visualizations for more accurate inspections

- Solve a wide range of vision tasks with height, volume, plane-fitting, and tilt tools

Optimize image formation in real-world settings

The 3D-L4000 with VisionPro includes patented, speckle-free blue laser optics that enable the system to capture higher quality images than traditional laser displacement sensors. This type of laser optics minimizes speckle and glare, common problems for 3D laser systems.

Reviews

There are no reviews yet.