-

Machine Vision

Machine Vision - Integration of visual functions such as positioning, measurement,

recognition, detect inspection and deep learning.

-

Vision inspection

Intelligent industrial camera vision technology To inspect, track and collect data at every step of the production process.

-

SMART FACTORY

Smart Factory system and analyzing data in real-time to reduce errors in your factory.

-

OUR SERVICES - PRODUCT

Helping the industry achieve highest efficiency both in the production process and quality check - Machine Vision Solution Accessories / Smart IoT - Industrial IoT Devices / SCADA / Machine Design

Vision Camera

Vision System design and installation service, vision technology with intelligent industrial cameras. To inspect, track and collect data at every step of the production process.

Barcode Reader

A barcode is a machine-readable representation of data related to the object it is attached to. Barcode readers read these codes in order to track the object throughout its lifecycle.

Automation Design

Automation System plays a huge role in development. Production methods that reduce costs Can control the quality of production better Increase production capacity and make the production line highly reliable.

Monitoring

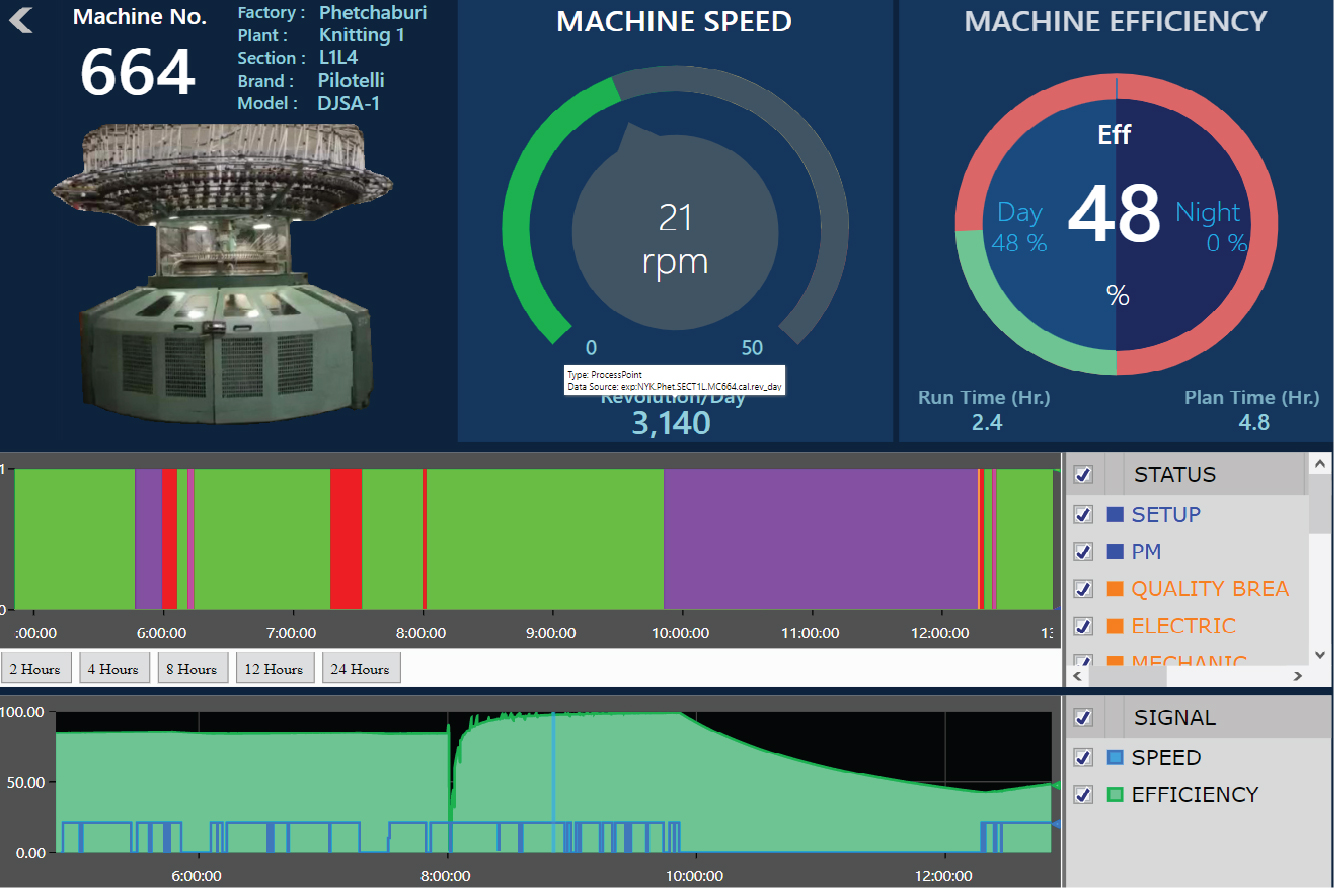

Shows the production time of each part. Therefore, an abnormality can be seen from the graph. show at each moment malfunction of the machine Represents the value of the measuring equipment that is part of the production.

Industrial IoT

The connection of machines, people and analysis system information together In order to get good and accurate information, it leads to It can track, collect data, exchange and display useful insights.

Smart Factory

Smart Factory, where all production lines work together automatically and seamlessly Not just individual machines Collaboration between machines All go through the control and command system.

Helping the industry achieve highest efficiency both in the production process and quality check

PROJECT REFERENCE

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo.

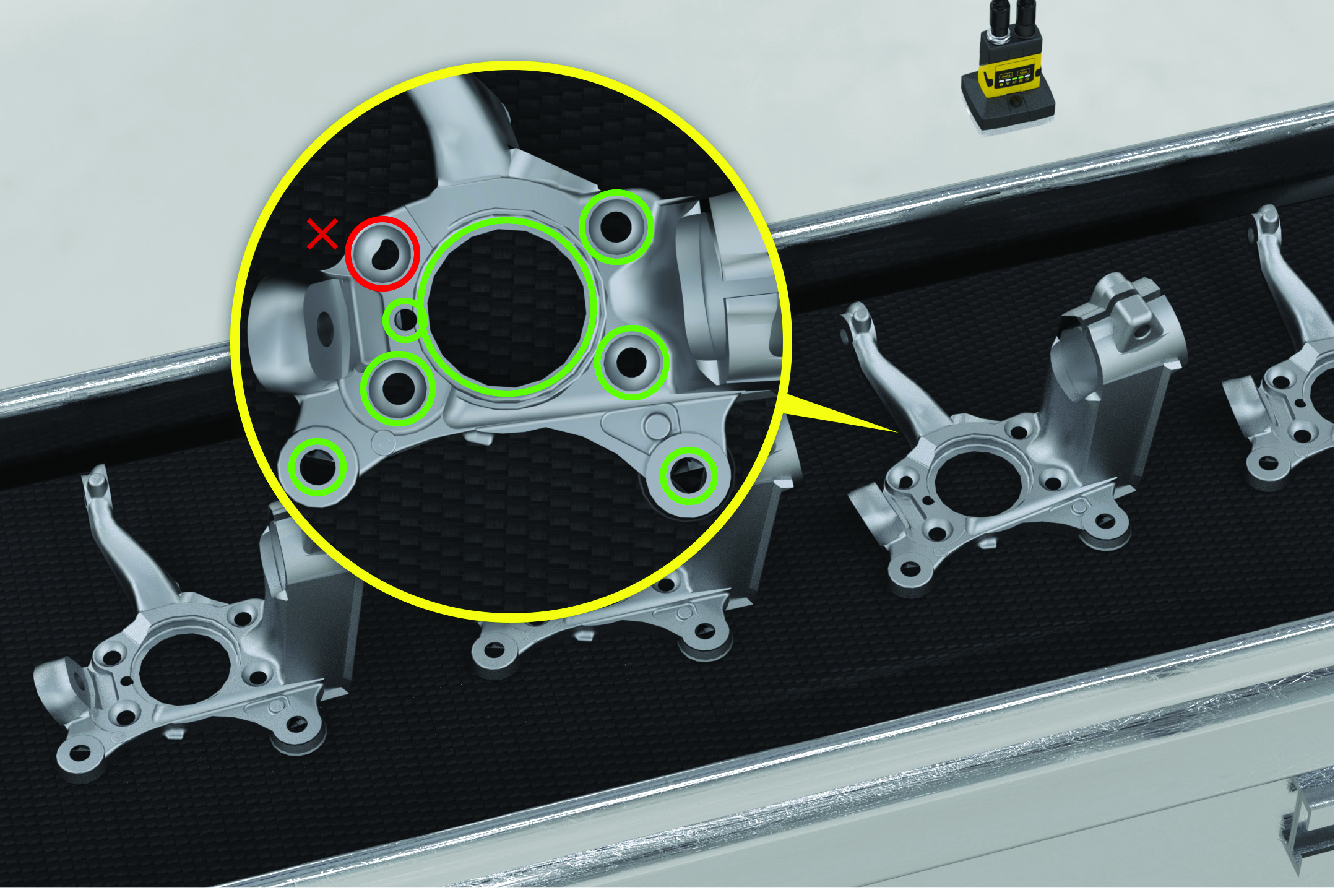

Steering Knuckle Inspection

Automated inspection regardless of part positioning. Inconsistencies often occur in the manual assembly of steering knuckles. Automating this operation is challenging since the position of the steering knuckle, its surface finish and the position of the characters used to identify it changes. Due to the manual assembly process, it is possible that the incorrect steering knuckle is assembled to the car which may result in recalls

Efficiency Monitoring

IIoT or Industrial IoT, stands for Industrial Internet of Things, is the connection of industrial machines and systems to the Internet in order to monitor, process and analyze data in order to increase efficiency, increase productivity and reduce costs because the IIoT system can detect, identify and manage production issues early in the process. As well as improving the operation of all machinery and equipment in the factory for highest efficiency.

Code Identification

Barcode verification is the process of grading the quality of 1D, 2D, and direct part mark (DPM) codes. An increasing number of regulated industries require barcode verification. Barcode verifiers provide guidance through the marking process to create codes which meet minimum quality standards. Cognex barcode verifiers use high quality optics, advanced algorithms, and simple software to demonstrate compliance to industry standard guidelines.

Machine Vision Design

The determination to develop the best automation system. To help raise the capability of operating in the industrial sector for highest efficiency with modern technology and move towards becoming a smart factory. We have a team of experts in design and install an automation system of experience in both of inspecting workpieces and controlling product quality. Including data management.

The Escape

Cognex, the world leader in Machine Vision and Industrial ID reader, Official Partner of WJ Machine Vision Co., Ltd., starts the first EP. of 2024. Let's update on new technology and products from Cognex to see what's interesting. We were honored by Khun Bam Sale Engineer from Cognex at Nana Coffee Roasters Ari.

WJ Machine Vision

WJ Machine Vision Co., Ltd. is Vision solution provider the determination to develop the best automation system to help raise the capability of operating in the industrial sector for highest efficiency with modern technology and move towards becoming a smart factory.

Machine Vision Lens

VS Technology, The company develops industrial lenses to meet the changing and diverse needs of customers in every industry. EP. 2 was honored to have an assistant sales manager for update new products and talk about how many types of machine vision lenses and how do you choose to use it?