Description

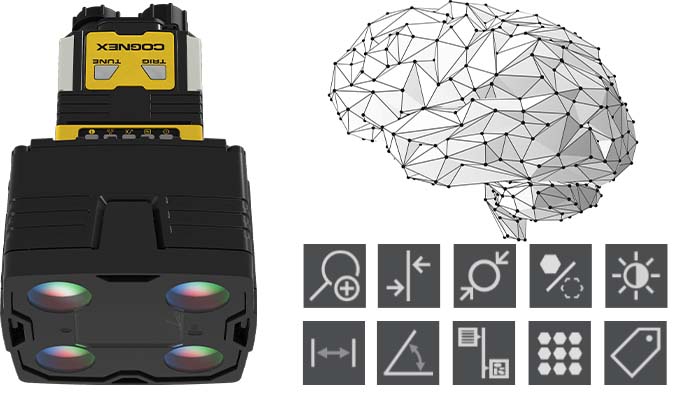

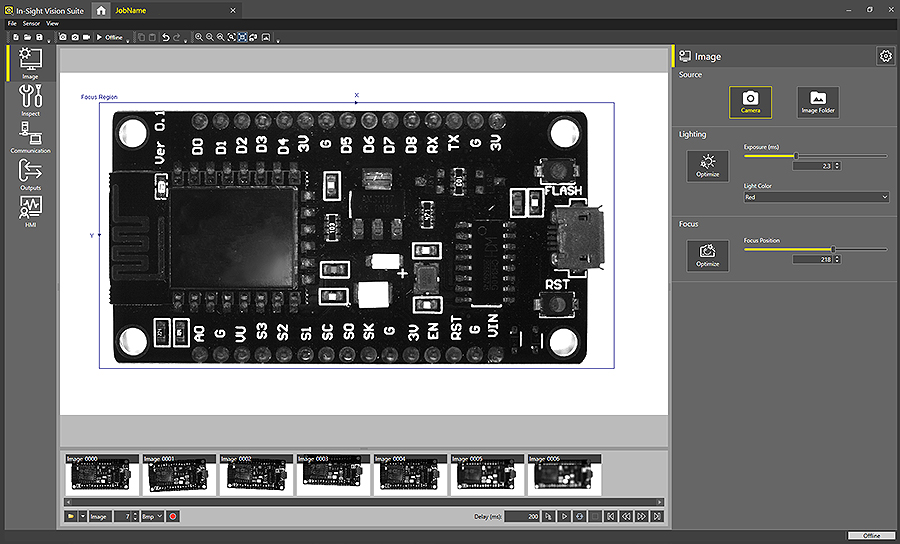

In-Sight 2800 Vision System

| In-Sight 2800 Specifications | |

|---|---|

| Image Sensor | 1 /2.8″ CMOS monochrome and color |

| Image Sensor Properties | 6.17 mm diagonal, 2.8 µm square pixels |

| Image Resolution Options | SVGA1 (720×540), 1.6 MP (1440×1080) |

| Electronic Shutter Speed | Min. exposure: 29 μs Max. exposure: Up to 10 ms (internal illumination) / Up to 200 ms (external illumination) |

| Acquisition | Up to 45 Hz |

| Internal Memory | 7GB |

| Lens Options | Multi Torch: 12 mm, 16 mm (High Speed Liquid Lens or manual focus lens) Mini: 6.2 mm or 16 mm High Speed Liquid Lens |

| Discrete Inputs | 2 opto-isolated |

| Discrete Outputs | 2 opto-isolated |

| Other I/O Points | 2 user configurable as inputs or outputs |

| Status Outputs | 5 status LEDs, audible beeper |

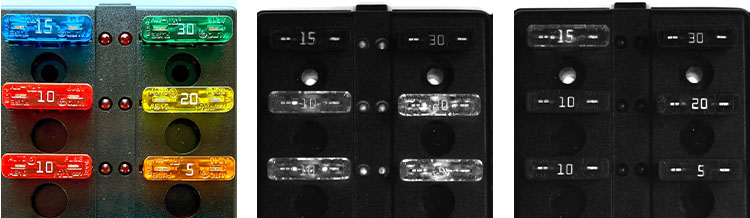

| Lighting | Multi Torch: High-Powered Multi-Color 4 LED ring light (red, green, blue, white) Mini: 4 LED small form factor light for 6.2mm lens (red, blue, white, IR options) Mini HPIL: 4 LED small form factor high-powered light for 16 mm lens (red, white options) |

| Communications | Ethernet interface |

| Protocols | TCP/IP, PROFINET, EtherNet/IP™, SLMP, OPC/UA, FTP |

| Power | 24V +/- 10% |

| Power Consumption | ≤7.5W |

| Material | ABS, Acrylic, Aluminum alloy, NBR, PC, PET, PMMA, Silicone, Silicone rubber, Stainless steel, TVP, Zinc alloy |

| Weight | 6.2 mm: 141 g; 16 mm: 169 g; Multi Torch: 290 g; Right angle configuration adds 50 g |

| Dimensions | Straight configuration 6.2 mm: 42 x 24 x 76 mm Straight configuration 16 mm: 42 x 24 x 91 mm Right angle configuration 6.2 mm: 42 x 79 x 38 mm Right angle configuration 16 mm: 42 x 79 x 53 mm Multi Torch straight configuration 12 mm / 16 mm: 69 x 66 x 110 mm Multi Torch right-angle configuration 12 mm / 16 mm: 69 x 104 x 68 mm |

| Operating Temperature | 0–40 °C (32–104 °F) |

| Storage Temperature | -10–60 °C (14–140 °F) |

| Operating and Storage Humidity | <95% non-condensing |

| Protection | IP67 |

| RoHS Certified | Yes |

| Approvals | EU CE, US FCC, TUV CB NRTL IEC 61010 |

1 SVGA options are monochrome only.

Reviews

There are no reviews yet.