Description

DataMan 475V Series Barcode Verifiers

Cognex barcode verification technology ensures the readability and compliance of 1D and 2D barcodes to industry standardization guidelines. Today most companies spot check codes one at a time using an offline, operator-based verifier which can be slow and cumbersome.

The DataMan 475V series inline barcode verifier can grade up to 20 codes per second. High-speed 100% verification and quality reporting can be done directly on your production line, preventing product waste and costly chargebacks. Immediate feedback and intuitive visual diagnostics provide operators with the ability to identify and correct printing and process control issues as they happen. For every code verified, detailed reports can be archived to ensure traceability, statistical process control, and compliance.

Label-based barcode quality compliance

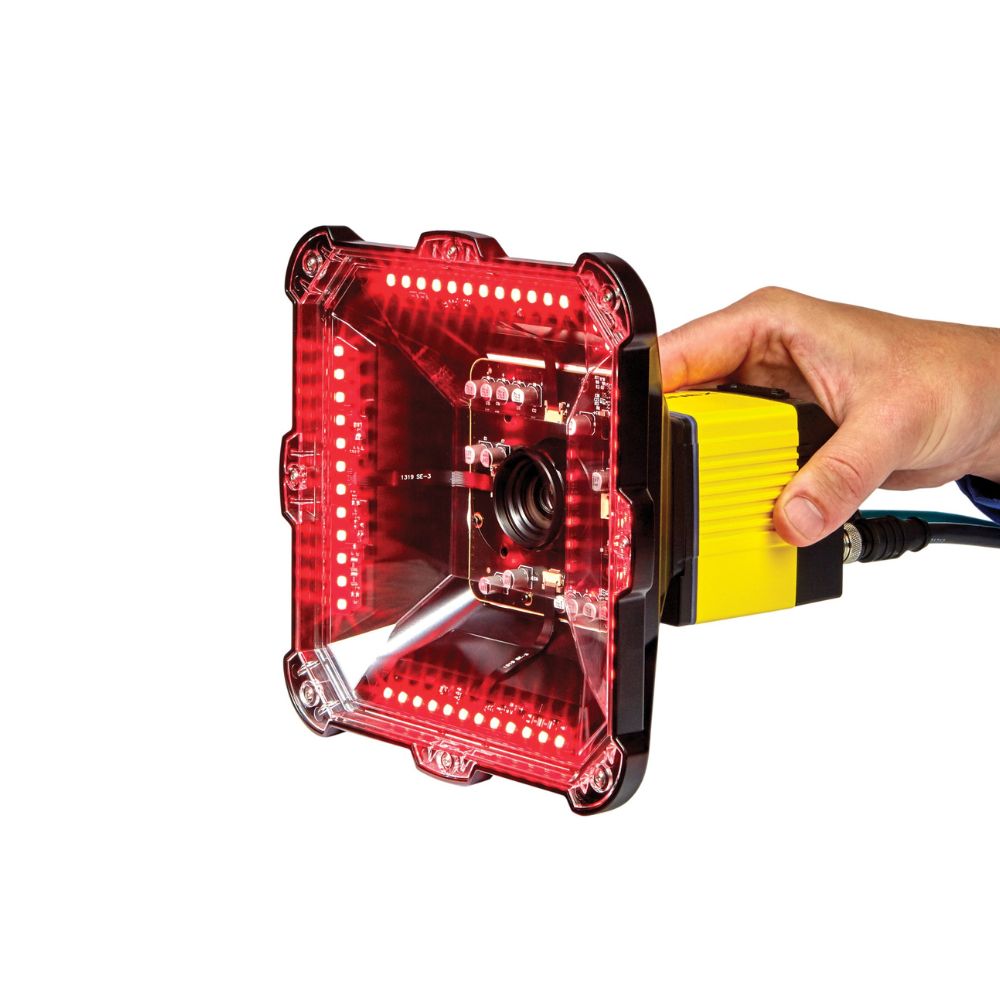

The DataMan 475V-label uses a four-quadrant, 45-degree lighting attachment for grading 1D and 2D label-based barcodes. This model is compliant with the International Organization for Standardization (ISO), allowing proper grading of 1D and 2D codes, according to the ISO 15416 and 15415 standards. The included calibration card and robust grading algorithms ensure that the DataMan 475V conforms to ISO and application standards while providing accurate and repeatable results.

Direct part mark (DPM) code quality compliance

DataMan 475V-DPM illuminates codes on textured, curved, and highly reflective surfaces using a multi-quadrant lighting attachment with 30S, 30Q, 30T, 45, and 90-degree lighting options. This model is ISO compliant and ready to grade codes in accordance with the ISO/IEC TR 29158 (AIM DPM) standard.

Reviews

There are no reviews yet.