Description

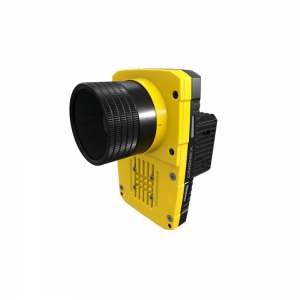

In-Sight 3D-L4000

Innovative system brings the power of 3D inspections to In-Sight

The In-Sight 3D-L4000 is a breakthrough in three-dimensional (3D) vision technology. This unique vision system combines 3D laser displacement technology with a smart camera allowing factory engineers to quickly, accurately, and cost effectively solve a wide variety of inspections.

The patented speckle-free blue laser optics, an industry first, acquires high quality 3D images and on-board high-performance processing powers a comprehensive set of true 3D vision tools, without the need for external processing. 3D vision tools are set up as easily as 2D vision tools thanks to the familiar and robust In-Sight spreadsheet environment.

Better image formation in real-world settings

The 3D-L4000 series’ patented, speckle-free blue laser optical system (left) enables the vision system to capture higher quality images than traditional laser displacement sensors (right).

A robust collection of true 3D vision tools

The In-Sight 3D-L4000 allows users to place vision tools directly on a true 3D image of the part, unlike typical 3D systems which transform its 3D images into a representational 2D height map for basic tool processing. True 3D inspections increase the accuracy of results and expands the types of inspections that can be performed. Better yet, because inspections are in 3D, users can immediately experience how the vision tools operate on the actual part or component.

The 3D-L4000 includes all the traditional 3D measurement tools users expect such as plane and height finding. However, it also comes with a full suite of 3D vision tools, designed from the ground up to leverage inspections in a true 3D space. Further, these vision tools were created with the simplicity of 2D in mind making them more accessible to the user.

In-Sight spreadsheet guides easy application development

The intuitive In-Sight spreadsheet interface quickly and easily sets up and runs 3D applications without the need for programming. It simplifies application development and streamlines factory integration with a full I/O and communications function set. The In-Sight 3D-L4000 provides the capability to combine 2D and 3D vision tools in a single job to solve a wider variety of applications.

Reviews

There are no reviews yet.